We provide complete line of services required for electronic equipment production.

Supply and stocking of materials

Components and materials used in production can be sourced by clients themselves or by us. Our stock of commonly used components and proven supply chains enable us to supply materials in fastest and most economical way. Unused components can be for future production or returned to you according to your preference.

PCB production by our partners

Reliable long-term partners utilizing latest PCB production technology manufacture provide us with any type of PCB in technologies commercially available today. Our engineers will fast-track PCB pre-production activities, partners will swiftly manufacture, and express courier services will ensure we have your PCBs produced and delivered for assembly within days.

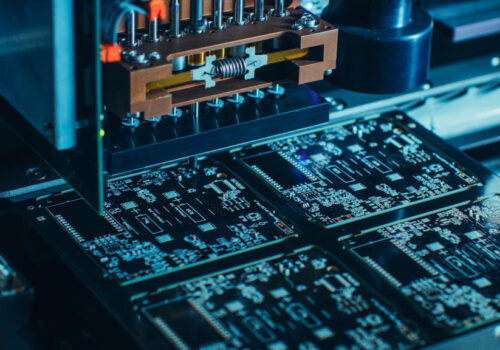

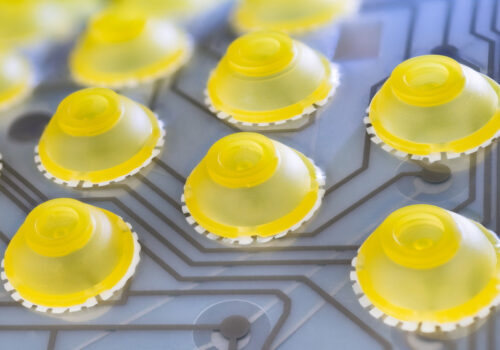

PCB assembly

With several assembly lines best suited for prototypes, small- and medium sized series, your products will be printed and assembled in shortest time. Our experienced production staff is ready to tackle possible issues which always arise during prototyping or first series of a new product.

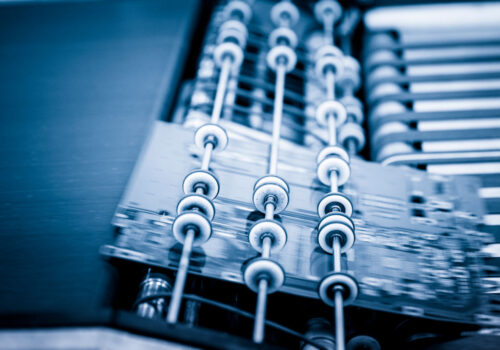

Soldering, optical inspection and cleaning

Using most advanced soldering technologies and machines – vapor phase, reflow as well as selective and wave soldering even for most complex designs will be properly soldered. Automated optical inspection makes sure that boards are assembled and soldered inside expected tolerances. Post-solder cleaning and rinsing of boards is regularly performed to remove any unwanted residues from the assembled modules.

Product marking

All products are marked with serial numbers, barcodes or QR code weather-proof stickers enabling full traceability of products during production and later exploitation. Custom marking with laser beams is also available.

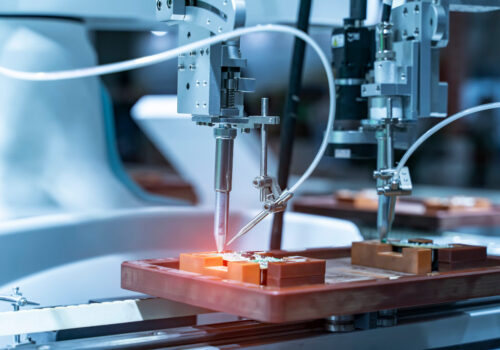

Multilevel automated product inspection

Each product undergoes automated optical inspection and tests using custom designed test devices and harnesses resulting with traceable test results.

Mechanical parts production by our partners

Housings, foil keyboards and other mechanical parts for your final product are manufactured by our partners and finally assembled in our production facility.

Final product assembly, unit & integration testing

After final assembly unit, integration and long-term test according to certified quality management system will ensure all products leaving the factory meet quality and reliability standards and your expectations.

Full insight and traceability

Using Client access portal, you have continuous insight into production status of your order, as well as traceability for your products manufactured in our facilities.